Published on 2/9/2020

Reason #3463 I dislike taking my car to a workshop:

— Henk Roux (@helloserve) January 4, 2020

They overtighten EVERYTHING.

I tweeted that because I had to use the power bar to get the top two bolts loose that attaches the air conditioning pump to its bracket. It was frustrating because there’s very limited space between the sub-frame, rail, engine block and the various pipes to work, and because it’s why I was again busy fixing the car. Workshop staff around here just do not understand what torque limits are.

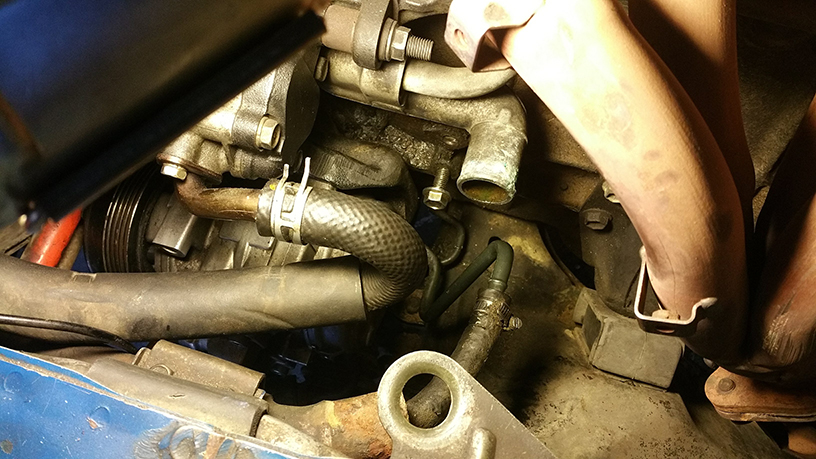

So, previously I wrote a short blog about that time I took the car to a very well renowned workshop around here to sort out the air conditioning. They ran into some issues with the pump leaking, but promptly sorted it out. Until about a month ago, when the whole thing came loose. I started experiencing belt slippage when I steered at slow speeds, and it progressed so I decided to park the car. And in fact, the entire air conditioning assembly was hanging from one bolt, the belt, and the flexible bits of pipe by this time. As explained previously, the air conditioning pump attaches to a bracket, which is attached to the block. There is a bolt in the front (which I had trouble with before) that goes through to the oil pump, and another one on the side of the block. These two hold the bracket in place. The one on the side was missing. I never heard it fall out while driving (it’s happened before with another bolt, I know what that sounds like!), so I was a bit surprised. Was it completely missing?

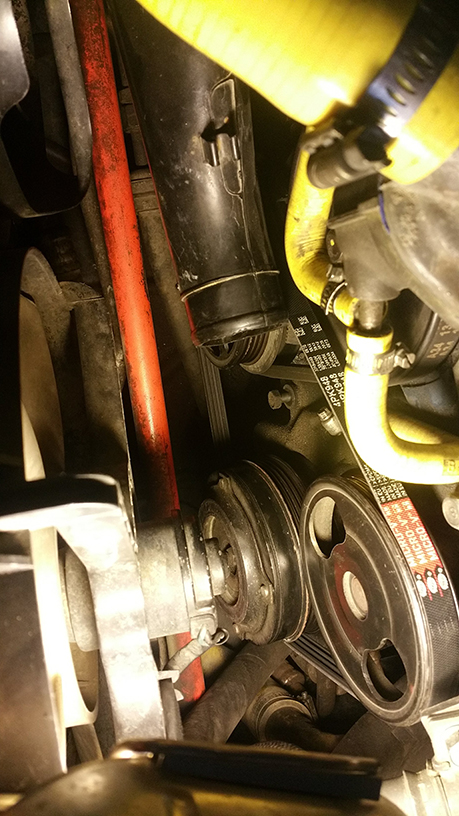

This was how far the front bolt had come undone when I inspected.

I started disassembly, and found that the stud was there but the head was gone. It had been sheared off in the workshop. I’m sure, since that’s the last time there was work done in that area. Thank ye old gods that front bolt didn’t wreck my oil pump as it slowly became undone over the last months of driving the car (recall that it stood in my garage for 5 months while I was dealing with the water pump et al.). How, by god, how tight must it have been to have held on for that long by itself? I have the official torque specifications document from 1989. The oil-pump-to-block bolts (one of which is this), is a mere 26 N.m. That’s screwdriver hand-tight!

After a lot of faffing and trying to figure out if there’s enough space to fit a drill, I discovered a second, threaded, hole in the block which lines up with a second hole in the bracket. It’s tucked in behind the pump itself and becomes inaccessible when the pump is attached to the bracket. There wasn’t a bolt there before, but it gave me a way out. I could get the bracket secured to the block without necessarily having to extract the stud from the sheared bolt. So I started to loosen the pump from the bracket, and of course I had to use the power bar on all four bolts on the pump. What is up with these workshop mechanics? Do they all turn green and rage when the customers aren’t around? As a matter of interest, these bolts’ specification is even less! Only 22 N.m. 🤷♂️

When everything was loose and sort-of moved out of the way I did attempt to drill out the stud. I got a right-angle Dremel fitting and everything, but the tool rotates too fast and I only managed a few millimetres deep before the metal tempered - not enough for the extraction bit to grab on and be effective. In the end we (some friends joined as usual!) just put the bracket back using the second hole, made sure everything is tight without drinking the special koolaid and ripping everything to pieces, and wrapped up. It’s not off the jack-stands yet, and I need to get a new battery, but it started up and we could inspect the belt alignment. So all is good, and time to get it out of the garage now for this new year.

Anyway, I’m really fucking annoyed by this, because it’s the same thing every time the car is at a workshop. Ford messed up (and lost?) the fittings for my front brakes. Some bloke at another workshop blew the soft-top’s window out with a power hose in an attempt to wash it. TWT had to send one of my wheels off for repair when they scored it trying to get a nut loose that their guy had tightened down just a few minutes prior. 🤷♂️ I only have bad workshop experiences on this car, and it’s why I do all the work myself as much as possible.

I have a ton of respect for John and Jason at CoolCo. They are very knowledgeable and have exceptional customer service. But it’s clear their workshop staff didn’t look up any torque settings. These are professionals that did apprenticeships and trained to do this. I mean, there isn’t a single bolt on the outside of this block that torques higher than 50N.m, with the exception of the timing gear bolt. It’s not a specialized engine, in fact it’s one of Mazda’s more typical engines: a stock standard B6 that was in the 323, Familia/Astina and other models. How in the hell do they get it so wrong?