Published on 9/2/2019

In a change of pace from the software blog series, I finally wrapped up the car's major service. It's showing 185 000 km, but that's the chassis mileage. I don't actually know what the mileage on the engine is since it was a replacement long-nose engine for my original short-nose. The supplier said anything up to 80 000 km.

So, since I had the new engine installed in 2011 with my clock showing around 120 000km, I inspected the timing belt on every service, unnecessarily removing the valve cover every 10 000 to 15 000 km. Last year I figured it would have to be replaced this year. And since I’ve done 65 000km myself already, it was fair to say this engine had probably done around 50 000km before. So, it's mid April and right on one year since the last service in 2018.

The center bolt

Stripping down the front of the engine is fairly simple. There are instructions for doing this all over the place. Soon enough you face getting that main center pulley bolt undone. Its torque setting is around 120Nm, so of course, your arms aren't enough. A while ago I got myself a 2-meter long metal pipe that fits nicely over the power bar, yielding excellent leverage (I also use it like this to loosen the center nuts on the hubs!). But you still have the problem of simply turning the engine over without actually loosening the bolt. In the past I would put the car in gear, bricks in front of the rear wheels and asked a friend to stand on the brakes, and then I would still turn that bolt through the engine, gearbox and differential and spin the wheels on the smooth garage floor so that red brick dust would rub off on them (One time I didn’t put the bricks in and the car almost moved itself off the jack stands). These days that's a bit tougher since most everyone has children and all sorts of school or sports engagements or whatever over weekends, and weeknights are really tough for us, owing to the kids’ routine. But then we hosted an Easter egg hunt for the kids with a bunch of friends, and one of the dads is a workshop manager for a local Honda dealer. He was keen to help.

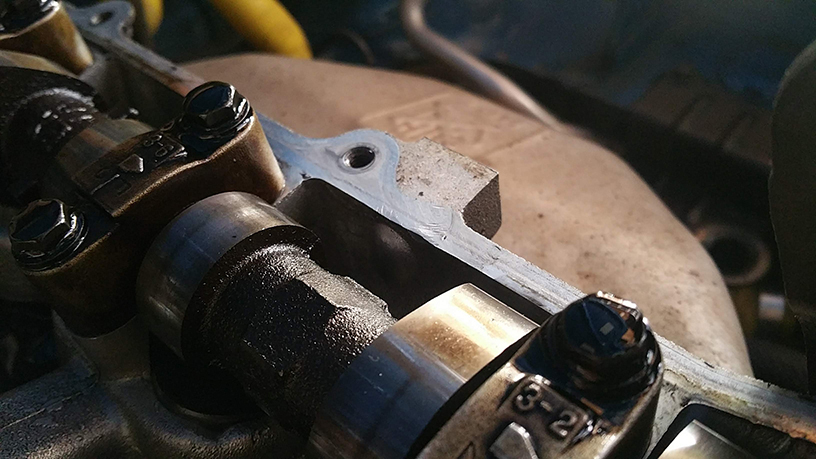

Unfortunately, I had put the entire car on jack stands since I wanted to replace the transmission and differential oil too, so standing on the brakes wasn't enough. Instead we tried the double spanner trick where you lock down the two camshafts using two 24 open ends. The belt simply jumped a couple of teeth on the cam sprockets. It was no good. I had to get the car down on the rear wheels, but this would take too long and we were in the middle of a sort-of party for the kids. We left the two spanners on the camshafts, got more beer and went outside. When I returned a few days later I noticed that the exhaust cam had turned on a lobe and wedged the spanner between it and the side of the head. This caused the soft aluminium edge to bend up and left a huge score on the level surface that the valve cover should seal against.

I tapped it back with a tiny hammer and lightly worked it down with a 1800 grit piece of sandpaper. It looked like it would be okay. I was quite annoyed by this, and more generally by the haphazard nature of how I’m working, and what that is doing to the car. So I decided to order the tool from Flyin’ Miata that would help me get at that bolt with ease, without having to put so much strain on the clutch and drivetrain, or worry about something slipping or breaking. This tool kit took more than a month to arrive, of course, owing to the multitude of bank holidays from Easter to middle May here in South Africa. So by the end of May, I had that center bolt loose and the old belt off. I easily replaced the main seal using the new fitment tool in the kit, and then, of course, I don’t have a new timing belt! I really did think I had one. There was a myriad of belts hanging off a nail on the side of my workbench, and what I thought was a timing belt was actually a toothed V-belt, for the alternator and water pump pulleys.

The kits

So now I had to get a replacement timing belt. And hey, since I had this new fitment tool for the cam seals, I figured why not. They weren’t leaking at all but they’re (probably) old and preventative maintenance is good, right! So I contacted the dealer and of course, they had wiped all the EPCs from 2005 and earlier off their system. They now effectively only support the NC Miata and later. The parts guy was kind enough to put in a request at Mazda South Africa but got no response. This is rather disappointing because it means that I would literally have to import everything from now on. Fortunately, there’s no shortage of places that stock parts in other countries, and it’s just a matter of finding the best deal. So I ended up ordering the Flyin’ Miata timing belt kit which included everything. And since the exchange rate was more favourable at that time, in particular, I also ordered the water pump kit (more preventative maintenance!). This took another two or three weeks to arrive, probably early or mid June. So in the meantime, I start my software design and development blog series and record U-boat gameplay videos and attempt to get the old water pump loose. I struggle a lot, but it won’t budge. And I don’t want to force it because, you know, I’ll probably break something. It’s always useful to have the replacement part handy to use as a reference. Photos on the internet don’t always convey the necessary. So I wait. After the parts do arrive we’re in the middle of a phenomenal cold spell here in Cape Town. It must have been close to zero degrees Celcius in the garage, and I was having none of this working at night in that cold.

The water pump

Somewhere in mid July I resume working on the car and continue trying to get the old water pump loose. The new one was indeed handy since I could confirm that all the leading edges were free and that I’m not missing any bolts. And also that there is a side inlet piece that has to be removed first. This piece and the ‘seams’ of the pump were almost indistinguishable from the old part because of how dirty it was. Cleaning up was a big theme during this service, and in total, I used almost half a liter of engine cleaner, wax and grease remover and other products. I got it off with a mighty heave, pulling what was probably an entire tube of gasket makers worth with it. Someone had tried to literally glue it in place! So a lot more cleanup was required.

.

.

There was a small O-ring in the new kit which I wasn’t sure about. No O-ring came off the old pump, and the only O-ring that I had found so far was where the thermostat housing attaches to the block, which was much bigger. I actually emailed the guys at Flyin’ Miata, and between their response and the instructions on Miata.net, I found the additional coolant pipe peeking out from behind the exhaust header. This meant that I had to also remove that side inlet piece from the main coolant pipe in order to pull off the small O-ring. As I tweeted at the time, replacing the water pump on an NA Miata is a real pain in the ass.

Putting this all back took a bit of planning, mostly around making enough time for myself to apply the required amount of gasket maker, letting it set, and then fitting the pieces. It’s tough with the kids’ routine in the week and all the happenings over weekends. These days, working on the car is more of a luxury than anything else. And of course, rushing this and not doing it right will mean leaking coolant, which will mean tearing it all down again and starting over. More on this later!

Seals, timing and covers

Then, it was around this time, I noticed rust on my cam lobes. The car had been sitting for so long and in such high humidity (the drought in the south of the country is broken!) it was inevitable. Nonetheless, I was pretty upset and distraught about it. I rubbed clean oil on the lobes, and the next day I wiped it off with a rag. It had gone, and I was really happy that it wasn’t worse because I hadn’t been paying attention. Always keep your lobes well oiled!

Then I set about pulling the seals from the cams to replace them. I broke two “pick and hook” tools and bent a small pair of pliers, but got them out. They were super tight, and it’s insane trying to get them out without scoring the metal surfaces. And remember, they were not leaking at all before this, but preventative maintenance is good, right? So I put in the two new seals using the fitment tool, which works very well.

I’ve set the timing on this car at least 10 times by now. Fit the belt around the bottom, tuck it in at the tensioner pulleys, over the one cam sprocket, and then count 19 teeth and wiggle and groan until it seats onto the other sprocket. Takes about half an hour to get it right, and a good assortment of swear words. This time took longer because I tried that cam sprocket locking tool, but found it more useful as a bottle opener than actually helping set the belt.

After that, I really should have tested my work, but alas more on that later. I set about refitting the plastic cover panels. They have rubber seals on the back along the edges, and years of heat cycles have really taken a toll on these. They are misformed and stretched to the point where it is impossible to fit them. The rubbers keep on bundling up and interfering with the pulleys, timing belt or something else. And they don’t seat in the grooves any more, so it constantly comes loose when you’re trying to wiggle the cover piece into position. I ended up applying gasket maker to actually glue them in place, after cutting them to make it fit properly.

After this, I wrapped up and fitted all the rest of the stuff I had taken off. Pulleys, coolant pipes, pump, alternator adjustment brackets, coil pack, and cooling fans. The car started up straight away, and then I proceeded to test my work.

Rust

My tests showed that the water wasn’t circulating! The top radiator pipe was scalding hot, while the bottom radiator pipe was very cool. Of course, it couldn’t have been the pump! The only other thing that inhibits the flow of coolant is the thermostat. Its purpose is to stay closed while the coolant (and thus engine) temperature is low, which helps the engine reach its peak operating temperature more quickly. Then the thermostat should open to allow flow and prevent the engine from overheating. Until it doesn’t. It’s happened before too this car and on this engine. One of the consequences of having the coolant system open for an extended period of time is rust. Typically you run a mix of distilled water and antifreeze which prohibits excessive rust from forming within the cooling system. But having it exposed while taking your time about replacing the water pump will result in some rust forming in the channels. When this dislodges it covers the thermostat which might very well stop it from working. And I think this is what happened. To take it out I obviously had to drain the coolant. It wasn’t green like when I had put it in just a day before. It was murky, and after letting the bucket stand for an hour or so, a rather thick layer of rust had sunk to the bottom. And the thermostat hadn’t been spared. It was also completely covered in rust as if I had just pulled it out of a puddle of mud. I didn’t bother waiting for a replacement. It’s not crucial. The only side-effect of not having it is having to be gentle with the engine for longer after a cold start. And of course you have to wait a really long time before the heater will work in winter, but that’s 10 months from now.

Preventative maintenance is good, right?

So now the car’s done. Everything is put back together again, and I’m driving it to work. There’s a massive oil stain in the parking bay. Oh dear. Maybe it’s just residual from the spillage when I replaced the oil filter? It’s impossible not to spill any, and there’s always a bunch that ends up on the lower control arm. Two or three days later, and there’s a lot of oil on my driveway. Something was wrong, so I go home early to inspect it while it’s still hot, before I have to do the afternoon school run. It looked pretty bad.

The two streams of oil on either side of the main pulley made me discount the main crank seal, and it was easy enough to discount the water pump fitment. There wasn’t any coolant here running old grime down the engine, it was too black. The only remaining sources, on the front of the engine at least, is the valve cover gasket, and the two cam seals. Yep, those two seals that hadn’t leaked before at all, but that I replaced because preventative maintenance is good, right?! I went ahead and ordered two more seals from Flyin’ Miata so long, on a hunch.

Ruptured

A few weekends, kids' birthday parties and other things later, and we’re in the middle of August. I’ve previously stripped the front of the engine down again to the point where everything except the timing belt is removed. It’s impossible to see where the leak is after it’s been stationary for so long, so I clean the front again (more engine cleaner!) and refit the airflow pipes. I needed to run the car to get the oil pressure up so that it could leak again, but I wasn't going to put it all back together. I ran the car with no coolant for a while (it runs really smoothly with no ancillaries) until I felt the first bit of warmth from the valve cover. Then I revved it a few times so that the pressure went past 4 kg/cm³. Initially, I didn't see new trails of oil, but upon closer inspection I see it had gathered at the base of the water pump. There seemed to be quite a bit pooling up there before it starts to run down the block and the sump. I start taking things off again, including the timing belt and cam sprockets and yes! There’s the leak.

I wasn't sure how the seal tore its inside edge, if it was my goofy install or what. Until I installed the new seal that is, because I was paying attention this time around. Immediately when pulling the seal over the end of the camshaft I saw that the spring had come out of its track on the back of the seal. And because of this the inner edge of the seal went slack and would surely leak oil. So, of course, I pulled it off and tried again, and it did the same thing. Then I used a pick tool to reseat the spring with the seal on the camshaft, being careful not to puncture the soft inner edge. This edge is so pliable in order to make a nice tight seal with the shaft, and the spring is meant to keep it tight against the shaft. I guess I was just very lucky with the install of the exhaust seal!

So while I was waiting for the new seal to arrive I started removing the upper control arms at the front. These units come with the ball-joints pressed in, and they cost a fortune to replace, for obvious reasons. For a while now there have been some aftermarket options to replace only the ball-joints, but you need a hydraulic press to remove the old ones and insert the new ones. I had to do this since one of the upper ball-joints was knackered. There're big bolts and nuts everywhere to undo, and it’s hard work, but rather simple. The one control arm simply popped off. The other one though, put up a massive fight. Here’s a rundown of ball-joint separation.

Firstly you reverse the castle-nut onto the end of the ball-joint and tap it with a hammer to dislodge. There’s limited space here, of course, so you’re limited in the size of hammer and amount of force. If this doesn’t work, well, I first try to somehow get my gear and hub puller in there to ‘push’ the ball-joint out. Again, the limited space is a problem and nothing is aligned, but this has worked for me in the past. I prefer to first try this because I really dislike striking massive blows with big tools on the car.

But this time it didn’t work. I tried multiple configurations of the tool, but that ball-joint was stuck in there. So I had to resort to my ball-joint separator. This thing destroys ball-joints indiscriminately. It took me three days of a lot of excessive hammering to get it loose. And there was collateral damage in the form of a few hits to the bumper and lip, to the end of the tool itself, and significant gashes in both the control arm and knuckle. It was very unpleasant to have to do it this way.

Still, it was out and I got the ball joints replaced at a reputable brake and clutch workshop. Within another day or so I had refitted all of the suspension parts and had the engine put back together again. Testing revealed no more oil leaks, as in none whatsoever. This is a great improvement from before. And so, again, this car as some battle scars to show for enduring another major service, but it’s still going strong and should clock over to 200 000km within the next few months. See you on the road!