Published on 3/15/2017

My handbrake light started staying on. I figured the switch went bad and thought nothing further of it. But then on my way to work in late Feb I hit the brake pedal. Nothing. Straight to the floor. It was the most out of control I have ever felt, and I include the moments like my pirouette, when I ripped the power steering belt trying to powerslide a 96kw car, and my time on the skid-pan at Killarney during an advanced driving course. That day I learnt that if the handbrake light stays on, check your fluid levels!

There was a leak at the one rear caliper. I figured it was the cover screw for the piston adjuster that I hadn’t tightened properly when I adjusted the handbrake. Of course, later I would also learn that if brake fluid even reaches that far back you have a much more serious problem. At any rate, I figured a good exterior cleaning would do the trick. It didn’t. After fitting new lines (why not?) and bleeding all round it was time for a test drive. The handbrake locked up on the one caliper and smoke was pouring out of the wheel well by the time I got it back into my garage. The leak on the other one was still there too, although now I could clearly see where it was leaking - the lever arm that gets actuated by the handbrake cable.

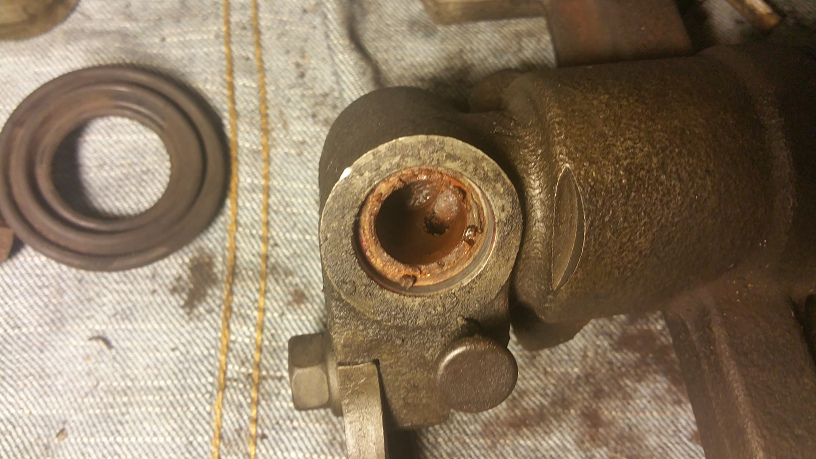

I read up, and yep, I had a much more serious problem. The O-rings around the piston adjuster spindles were most like shot. So I took it all off again and started the total disassembly process. It’s not difficult, apart from the cir-clips that holds in the spindles. They have to come out in order to remove the spindles so that you can remove the lever arm. If you don’t have the proper pliers you might still get them out with two pins. And even with the correct pliers, I had to file down the tips to get them small enough to properly fit into the little holes to squeeze effectively.

With everything removed the result was startling. Clearly a lot of dust and grime had worked its way into the calipers’ mechanisms, wearing away at the O-rings (that old African heritage of my car again). But then the brake fluid started coming out and created a grimy slimy mix that somehow held together for a long time, until I started messing with the piston adjuster last year in an effort to adjust the handbrake.

The cleaning process isn’t hard, but there are quite a few things to look at, plus I have to get new seals, boots and O-rings which are on order from the UK. Here's a good step-by-step guide if you're interested.